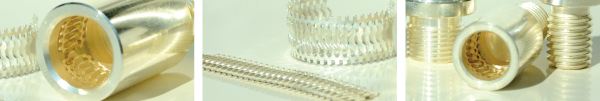

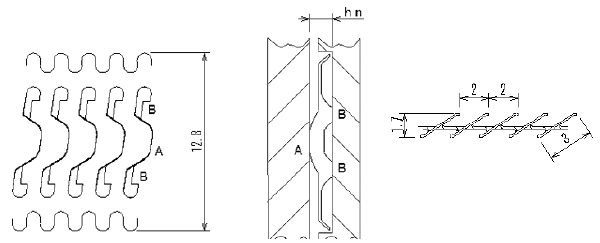

This contact is a one-piece structure, which is cost-effective and also capable of supplying a large amount of current. Additionally, the manufacturing process is unique as it involves stretching while die-cutting the beryllium copper, not just ordinary press molding, which creates a large spring range of motion. Furthermore, the contact has a certain angle relative to the insertion direction, which reduces wear and abrasion on the mating side during insertion and extraction, significantly extending the life of large-current and high-current connectors.

| Material / Treatment | BeCu Special Quenching Process |

|---|---|

| Standard is Ag plating | |

| Surface Treatment | Changeable to Pt, Au, Rh plating, etc. |

| Thickness | 0.15mm |

| Operating Temperature | -270℃~180℃max |

| Contact Resistance | 800μΩ / Louver |

| Continuous Rated Current | 25A / Louver max |

| Permissible Short Circuit Current | 850A / 1 sec / Louver ・ 550A 3 sec / Louver |

| Surge Current | 2000A / Louver |

| Thickness | Contact Force | Sliding Force | Usable Range of Motion | Maximum Movement Range | |

|---|---|---|---|---|---|

| mm | N | N (μ=0.35) | hu max(mm) | hu min(mm) | mm |

| 0.15 | 4 | 1.4 | 1.4 | 0.9 | 0.5 |